A seamless workflow, optimized for quality, efficiency, and precision across every stage of production.

Knitting

Dyeing

Sampling

Cutting

Sewing

Pressing

Finishing

Packing

Special Process: Printing & Embroidery can be integrated at the Sewing stage for custom finishes.

Sustainability index

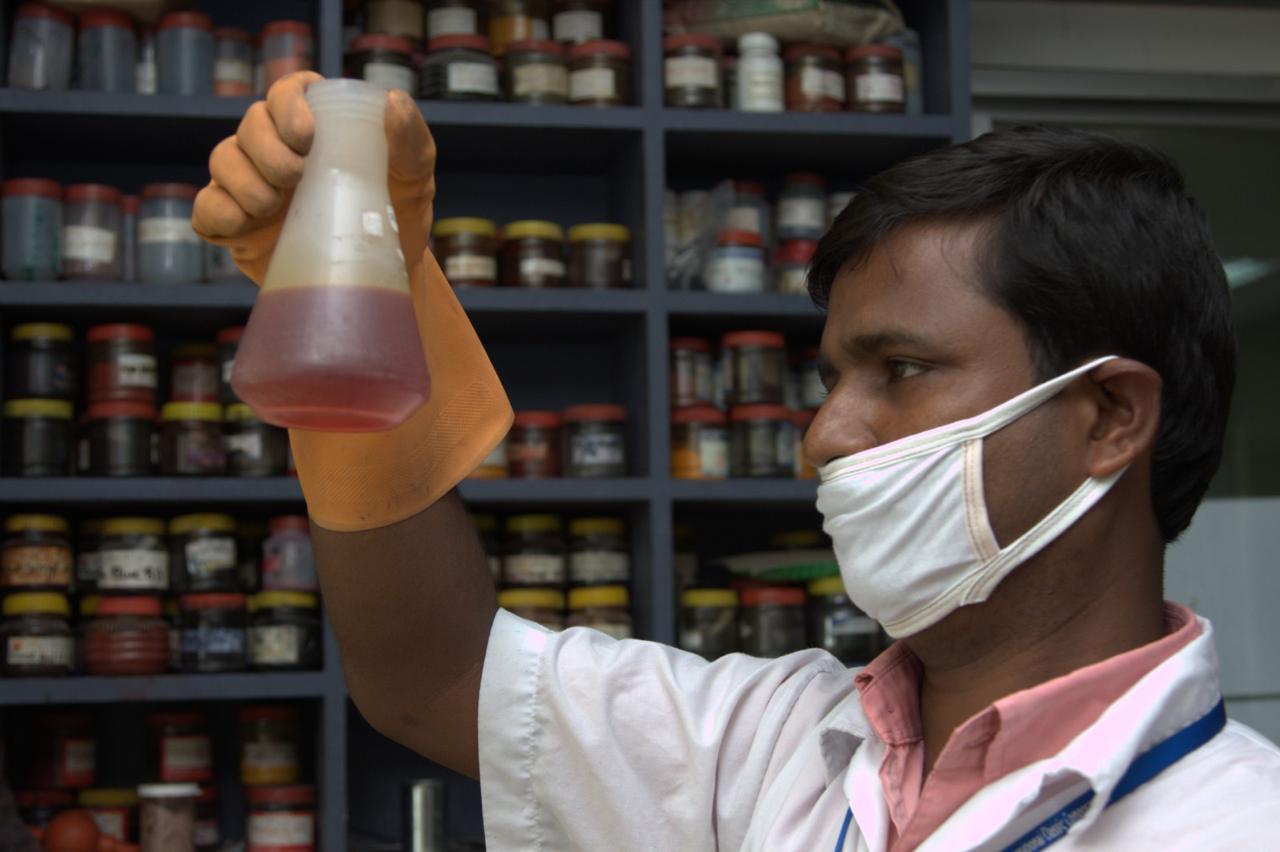

Zero hazardous chemicals

Chemical tracking platform

Resource tracking system

Enterprise-grade chemical tracking and compliance management platform

Real-time monitoring across all operations

Automated documentation and process control

Safe chemical handling standards

Platform ID

Platform ID BHE054747

Integrated solution for comprehensive chemical management, ensuring operational excellence and environmental compliance across all manufacturing stages.

sss

Through these strategic initiatives, we're committed to reducing environmental impact while maintaining operational excellence across all manufacturing operations.

"Our commitment to sustainability supports both the environment and long-term operational excellence."

Capture and collect rainfall for reuse

Biological treatment for wastewater

Groundwater recharge and strategic reserves

Process water and landscaping applications

Through integrated water management strategies, we've built comprehensive systems that conserve resources while maintaining optimal production efficiency and environmental responsibility.

"Our green initiatives promote harmony between industrial growth and environmental preservation."

Green belt development around factory premises

Use of low-water and native plant species

Training staff on sustainability practices

Our green development programs enhance biodiversity, improve air quality, and engage employees in building a cleaner, greener future.

Implement advanced treatment technologies (e.g., MBR, RO) for complete water recovery.

Reduce dependency on groundwater and natural sources through recycling.

Prevent contamination of surface and groundwater with untreated effluent.

Align with global sustainability standards (ZDHC, SDGs, DoE).

We are currently operating a Water Treatment Plant with a capacity of 125 m³/hour, ensuring clean and compliant water for sustainable production.

Our Water Sustainability Plan focuses on conserving, reusing, and responsibly managing every drop — ensuring long-term environmental balance and operational efficiency.

Increase storage capacity and collection points, including large-scale tanks and rooftop systems.

Upgrade our water treatment plant, install RO & MBR to improve efficiency and enable more water recycling and reuse.

Develop and maintain recharge systems such as ponds, percolation pits, and geo-bags to replenish groundwater.

Implement water-saving technologies and processes to reduce overall water consumption in production.

Strengthen monitoring protocols to ensure compliance with environmental standards.

Conduct awareness programs focused on water conservation and sustainable practices.